Internet of Things (IoT) and sensor overview

Internet of Things and Sensor Overview

The Internet of Things provides a way to use sensor devices and various cloud solutions to gather, analyze, and act on data. Devices are broad-ranging and include manufacturing line, trucking, connected cars, wearables, smart homes and appliances, and much more. The number of connected "things" is expected to reach over 20 billion or more by 2020. Many success stories already exist in various industries -- and the trend is growing rapidly.

To make the most of sensor data, you have to be able to collect, process and analyze the data; One Point's unique focus on IBM data and analytics portfolio provides the answers: The key is analytics. Once you have the data converted and stored in the cloud or your local servers, that data can be analyzed and acted-upon to determine trends, find faults, and improve processes. IBM provides a number of historical and predictive solutions that provide value at any part of the process, providing a more efficient and profitable operation. Here are some resources, followed by an example scenario below.

- One Point analytics overview and value proposition

- IBM IoT overview video

- IBM IoT overview and sample video

- Automotive success story: problems solved before they became problems

- Predictive maintenance and quality solutions

Simple Example and Process Flow for Assembly Line

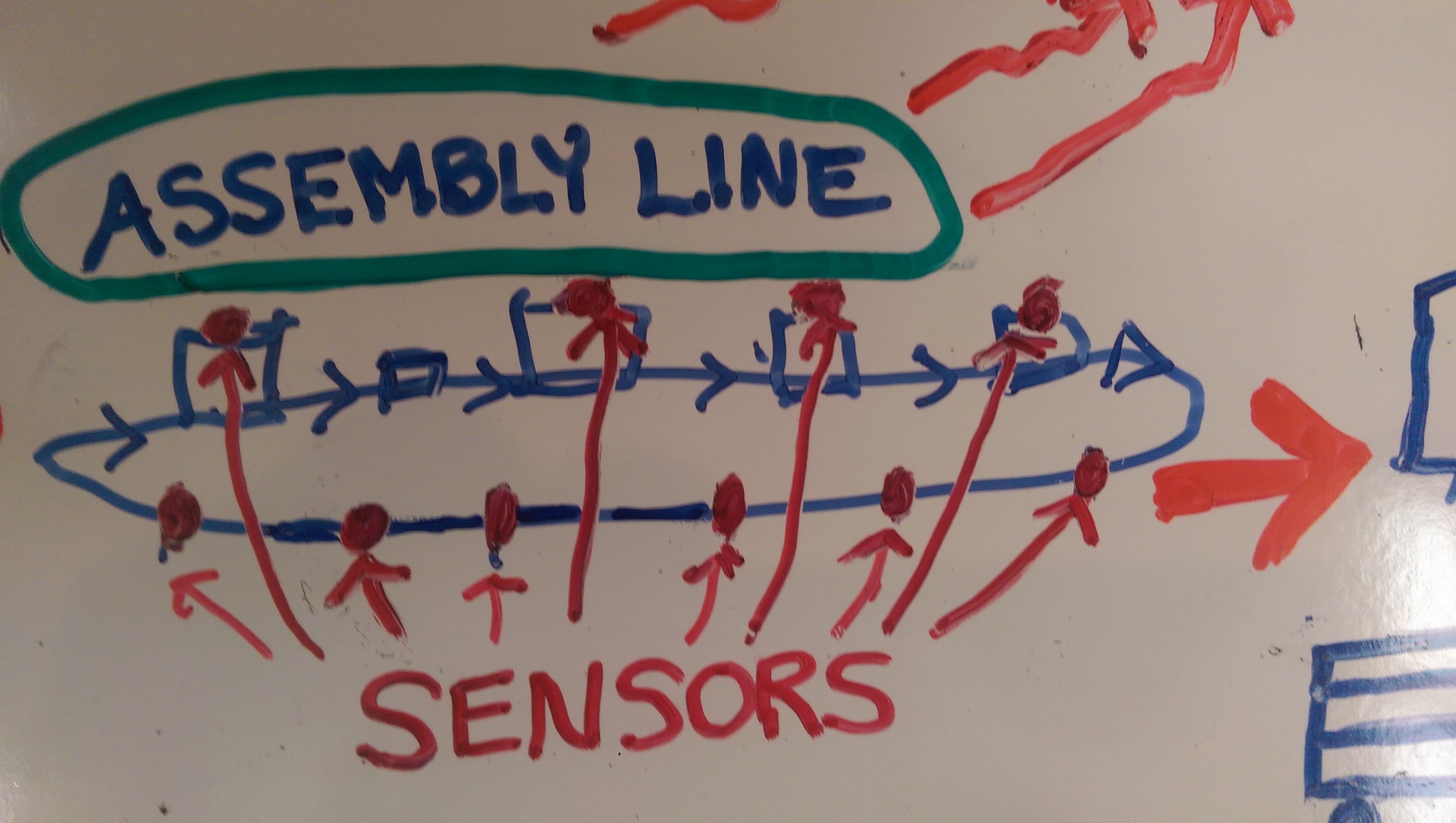

While it takes planning and time to implement a successful system, there are a variety of IoT and data solutions that can make that process easier and allow for a quick and inexpensive Proof of Concepts (PoC). Taken from our IoT Whiteboard Session, here's a simple example of how data is captured and analyzed for real-time and long-term predictive results and process improvement.

|

1) Implement Sensors on the Assembly Line. Through a variety of sensors that can be placed directly on assembly lines, items going down the line, RFID tags, and more. This data can be collected and acted-upon realtime, then aggregated and sent through a local gateway for later analysis and proactive maintenance. There are many sensor solutions -- some of which are built into machinery. Here some examples of manufacturing sensors from TI, mostly priced under $10.

|

|

2) Collect Sensor Data on Local Gateway Devices. Data collected from local sensors can be fed to gateways which can be used for real-time monitoring/analytics, then fed to the cloud or other databases for analytics. Here's an overview and some gateway examples from Shaspa.

|

|

|

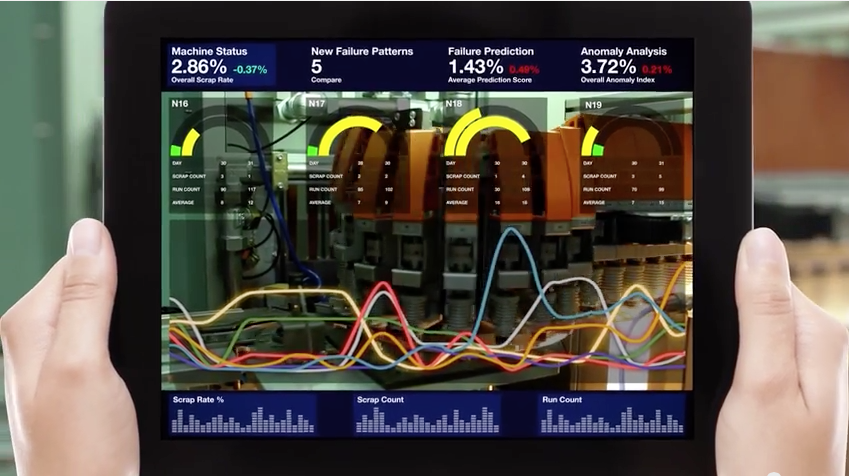

3) Take real-Time Action on PCs and Mobile. Local sensors and gateways can transmit data to a variety of mobile devices and computers, allowing for a real-time view of the assembly process. As the result of the overall analytics process, thresholds can be set on these devices, allowing shop-floor and plant managers to act proactively when a potential issue is predicted to occur.

|

|

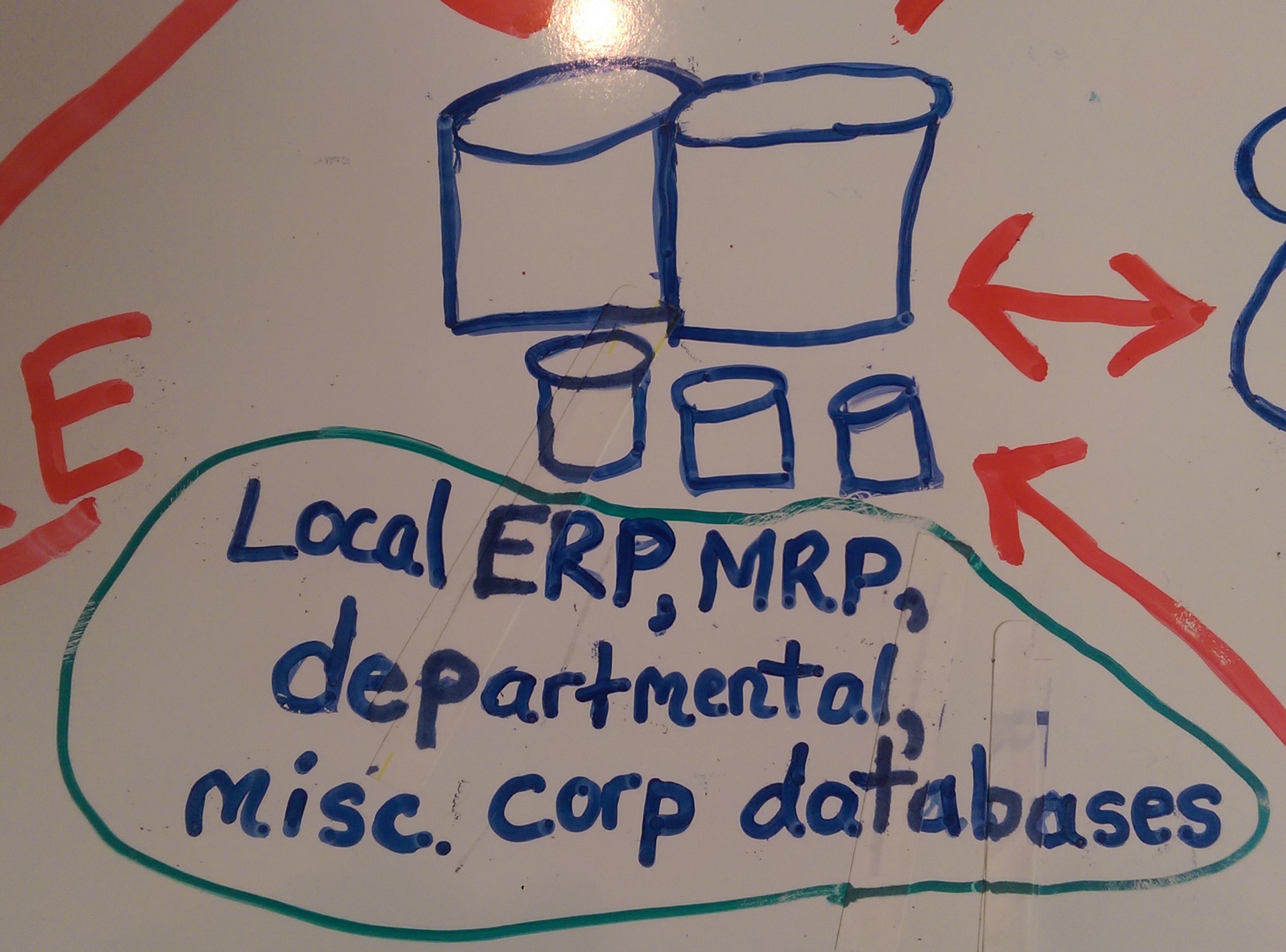

4) Store Data in the Cloud or Locally. Here are an abundance of cloud solutions such as IBM SoftLayer and numerous other vendors as well as private and shared cloud. These many options provide companies the ability to use pre-built databases (e.g., IBM Cloudant) or a plethora of pre-built Dev Ops environments (e.g., IBM Blue Mix) to quickly and very cost-effectively roll out solutions and add immediate value, greatly reducing CAPEX and IT burdens. Data can also be sent to traditional in-house database systems using traditional databases or IoT-specific modern database systems.

|

|

5) THE KEY: Historical and Predictive Analytics. The wealth of data in a company's entire process provides tremendous opportunity for analytics and reporting, dashboarding, scorecarding, IBM Predictive Maintenance and Quality, and varous other predictive solutions but the data is often ignored or you may not know how to act upon it. This entire ROI circle is enabled by the ability to access, translate, and display data in formats that can be used by finance, operations, marketing, sales, and any department. Peruse analytics options to transform your business -- now and in the future. |

Examples of IBM IoT Solutions